Heat and Control provide a wide variety of innovative and dependable conveying and product handling systems to move product through the line as efficiently as possible.

Horizontal Motion Conveyors and Feeders

The industry’s leading solution, FastBack’s patented slow-forward and fast-back horizontal motion technology has transformed the conveying market. With over 20,000 units worldwide, FastBack is the conveyor of choice for challenging products like salads, snacks, fresh chicken, cookies, candies, and many other food products.

FastBack Horizontal Motion Conveyors

Originating with the FastBack Horizontal Motion Conveyor the FastBack range has developed a series of feeding, proportioning and laning product handling solutions. All offer the renowned benefits of the gentle transport of product by cycling through slow-forward and fast-back horizontal motion. Neither damaging or segregating product nor disturbing coatings, while providing the fastest product travel rates, and maximising product distribution efficiency.

Flexible and efficient, processors can depend on FastBack to reliably convey hard-to-handle products. It is energy efficient, quiet, versatile, and comes with a 5-year drive train warranty.

FastBack’s clean and sanitary design reduces pan buildup and sanitation down-time -making it ideal for full washdown environments.

Further developments to the FastBack range include:

Blending Systems

FastBack Blending System

Achieving the complex task of producing balanced blends by providing consistent component streams, metering components with dependable accuracy, and conveying blended components without segregation. Make consistent mixes and produce a product with high quality. Operators can easily adjust the component streams as needed to consistently replicate their recipe, giving operators complete and intuitive control over the entire process.

FastLane Slicer Infeed Conveyor

The space-saving FastLane combines the gentle horizontal motion of the FastBack Model 260E-G3 with a multi-lane pan that singulates product for delivery into multiple rotary slicers, reducing slicer overload and improving slice quality. Effective singulation increases production, producing more quality slices and less scrap with a consistent, singulated feed to each slicer. FastLane spreads potatoes evenly–no flooding or product damage and ensures that only available slicers receive successive product while unavailable slicers remain unfed.

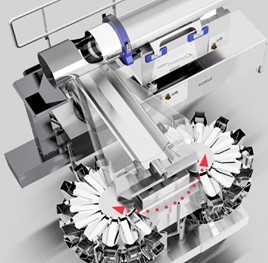

Left Right Center Diverting Weigher Infeed

FastBack Left Right Center Diverting Weigher Infeed

The FastBack Left Right Center (LRC) is a compact double multihead weigher feed solution designed to provide a precise, consistent product stream to Ishida’s patented back-to-back CCW 218 twin weighers. An intelligent solution that ensures long, continuous runs, the combination of patented Revolution Gate distribution, Double-V product stream conditioning, and LRC feeding provides unprecedented bagmaker runs for increased production time.

Revolution Proportional Gate 3.0

This ground-breaking proportional distribution system by FastBack uses unique cylindrical outlets that rotate to divert a proportional portion of product, so the main product supply continues to flow as it allocates amounts to individual weigher/bagmaker stations. Downstream stations are no longer “starved” and do not need to wait for product. Improve overall performance and maintain consistency – the patented design introduces various advantages that make it the premier gate in the industry. Proportional, granular feeding keeps product uniform and improves packaging, and on-machine seasoning performance adds 1 to 5% improvement in overall line efficiency. The gentle, innovative design diverts product without creating a single pinch point which reduces typical product breakage by 4 or more percent.

WeighBack Weigh Conveyor

Designed to improve the productivity of your weigh-conveying operations with better accuracy, gentle conveying for less breakage, and less maintenance than standard weigh belts. The integration of gentle and clean FastBack horizontal motion conveying with direct load cell weight measurement delivers precise mass flow data to processing, seasoning application, or packaging equipment. It offers precise weighing at up to 10 meters per minute and no tools are required to access load cells.

Other Product Handling solutions that have been developed specifically for Snack processors include:

Accumulation

Let your processing and packaging area run without interruption and maintain peak line efficiency by controlling product flow by taking advantage of accumulation systems to temporarily store product or keep it moving in a steady flow to and from processing and packaging areas.

Accumulation systems can improve full line efficiency managing output from high volume processing systems such as fryers and freezers until the time is right to deliver it to equipment downstream. In addition, they reduce waste and product degradation caused by sudden packaging room stoppages or slow-downs by providing a temporary place to hold product, rather than discarding it.

Chip Sizing

Offering efficient sizing and separation of cooked potato chips, large and small, to ensure quality product is consistently packaged in the right bag sizes. Experience reduced bagmaker stoppages and faulty seals by ensuring the right size of chip is placed into the appropriately sized bag.

Change the size parameters instantly and easily via hand wheel or optional motorised drive. The simple patented shaft spacing system eliminates moving parts and binding issues associated with other systems. Select single-, dual-, or triple-deck sizers for the most efficient product sorting rates.

Don’t risk your business with inferior, out-of-date technology. Visit one of the test facilities for a free demonstration or contact Heat and Control New Zealand on +64 9 274 4182 or get in touch via [email protected] or www.heatandcontrol.com

About Heat and Control

Established in 1950, Heat and Control is a privately-owned company with a global team that has built an extensive knowledge bank and developed a wealth of experience and expertise. Access to production and technical support from a network of engineers, food technicians, field service technicians, skilled tradespeople, and support teams provide food manufacturers with confidence to achieve production goals.

- Ten manufacturing facilities, 11 test centres, more than 30 offices globally

- Testing, design, engineering, manufacturing, installation commissioning, user training, spare parts, and provision of after sales service.