ON ONE of New Zealand’s busiest retail days, the tiny pioneering town of Eltham in South Taranaki is decidedly quiet.

ON ONE of New Zealand’s busiest retail days, the tiny pioneering town of Eltham in South Taranaki is decidedly quiet. It’s mid-morning on a fine Christmas Eve, and the back streets fringed with faded abandoned old merchant stores held together with peeling paint appear deserted by the gift-buying farming community that surrounds it.

You can almost see the ghosts of colonial traders who built these side shops standing in the boarded-up windows lamenting the exodus of Christmas shoppers to the big lights of Stratford and New Plymouth to the north, and Hawera to the south. They cluck to each other, shake their heads and watch as the cars pass by along the main drag, wondering what has happened in the short space of a century.

If, however, instead of whipping through the quaint town towards the urban centres you turn left off the main road in the middle of town and head down Bridge St, the other face of Eltham is revealed. Away from the speeding traffic, over the railway line and you’d be forgiven for blinking twice as you enter a commercial compound filled with cars, people and activity.

It’s almost enough to make you brake and wonder what alternative dimension you’ve unwittingly driven into. Car parks are scarce and people scurry between an assortment of different complexes that hug the rail line. It’s as if the colonial side of Eltham has gone, replaced instead by 21st century technology.

The only clue to where you are is in the familiar branding of Fonterra, one of New Zealand’s largest co-operative companies. Its logo seems to permeate through everything you can see…in fact, if you were airlifted into the town from deepest Africa and had no idea where you were, it would be easy to think that the tiny town of Eltham was indeed called Fonterra.

The company has operated sites in the town since the late 1880s, with Collingwood St handling secondary milk produce. It’s the fourth largest Fonterra site in New Zealand, and deals with products such as frozen, shredded and processed cheeses. Fonterra employs 160 staff in Eltham, and has a profound effect on not just the town but also the Taranaki community. It’s a partnership the company is proud of; a plant that operates 24 hours per day at least 50 weeks a year in any part of New Zealand would impact just as strongly.

Ask site manager Brendon Birss ‘Why Eltham?’ and he breaks into a smile. Why not? he says. “We have more than 100 years of cheese-making history in this town, which sits centrally in Taranaki and has easy access to other commercial centres. We are committed to Eltham. There’s a relationship here that’s unique and this project illustrates that.”

What he’s referring to is a $32 million project to double the site’s sliced cheese-making capability for customers in Australasia, the Middle East and South East Asian countries like China, Taiwan and the Philippines. Amongst those clients are high profile fast food companies like McDonalds, Subway and Burger King, which means making to order for an ever-more demanding fast food market in the Southern Hemisphere. These companies use around four million slices of cheese a day…enough each year, in fact, to circle the world three times around.

Of importance is the burgeoning demand for packed and unpacked cheese slices, for which the company has expanded its facility significantly to accommodate a new processing machine from Germany. Once fully completed this month, the site will be able to make around 2.3 billion slices of cheese each year…at 2000 slices a minute, that’s both impressive and awe-inspiring. It’s one of Fonterra’s most in-demand consumer and food service products.

As director of New Zealand manufacturing for Fonterra Mark Leslie says, the company needs to constantly follow trends in key markets and work with customers to help meet their growth with investment.

“One of the most exciting things,” he says, “is that our consumer and food service expansions are almost entirely demand-led, meaning from the moment the product comes off the line, it’s already earmarked for customers in more than 100 markets around the world.”

FOR Nathan MacDonald, the project has meant two years of intensely hard work and a trip to Germany to visit the manufacturers of the new machine made by Mettler Toledo that Fonterra has imported for the production of cheese slices to assist with the expansion. In that time, he’s liaised with installers and trainers, operations and maintenance staff, building contractors and local tradesmen. It’s satisfying, he says, to see the operators with smiles on their faces.

“To them, it’s a bit like going from a manual car to an automatic one with electric windows,” he says of the new equipment. “We’ve had operators asking to come in on their days off to see it being run, and some wanted to swap shifts so they could be the first to experience it. It’s been a big adjustment for some of them, but they’ve been really excited.”

When you enter the new site space, an overwhelmingly delicious aroma of hot cheese fills the senses. The machine takes cubed cheese and grinds it like mincemeat before supplementing it with additives to suit a myriad of client specifications before blending it together and heating in the oven. It’s a bit, Nathan says, like making a cake at home, with individual changes to recipes to suit consumers. McDonalds, for example, likes a different colour of cheese than that typically produced by New Zealand.

The machine processes around 1.5 tonnes of product an hour, and can run up to 2000 individually wrapped slices per minute. It produces approximately 80 different individual products ranging in size from 100g to 768g packs, and outputs more than 8000 tonnes of individually wrapped cheese slices per year.

In anyone’s book, that’s impressive. Nathan looks at the new machine with something akin to awe. “She’s pretty impressive,” he says, watching the produce march along a conveyor belt. “We’re pretty proud.”

ELTHAM may boast many Fonterra ‘firsts’, but it has plenty more to be proud of. ..and the town’s residents celebrate that regularly. The classic pound of butter was first made there in New Zealand’s inaugural commercial butter factory in 1887, and it was the first town to get a tarred macadam street in 1906. The Pease Building, built in 1909, was the first building in the country to have a suspended concrete floor; it’s the site of the first ever World Axeman’s Carnival (1911); and the first rotary cowshed was designed in Eltham.

Its famous exports – including All Blacks Geoff Old, Roger Urbahn, Bryce Robbins and Brian ‘Jazz’ Muller, and Black Cap Martin Donnelly – is topped by Chew Chong, a Chinese immigrant first attracted to the region after discovering an edible fungus similar in taste to a highly prized Chinese plant considered a delicacy. He singlehandedly supported many Taranaki dairy farmers struggling to make ends meet by purchasing ‘Taranaki Wool’, which was for some the only source of ready cash in the early 1880s.

Chong bought butter too, and sent two kegs to England in 1885. This marked the beginning of New Zealand’s flourishing dairy export industry and, two years later, he opened a dairy factory beside the Waingongoro River bridge in Eltham, importing top-class cream separators and winning the coveted silver cup for the best half ton of butter packed suitably for export.

Fonterra, as well, has been a high profile company in the area for more than 100 years. It provides employment for 10 per cent of the Taranaki workforce at its Eltham, Kapuni and Whareroa sites, and contributes as an industry around $1 billion to the region. It’s not surprising that of the 1700 herds in Taranaki, 1600 produce milk for Fonterra, and the company collects more than 14 million litres of local milk a year. It’s proud of its Grass Roots fund that has supported more than 40 community groups in the past three years.

Venture Taranaki ‘s general manager – economic development Michelle Jordan doesn’t mince her words talking about Fonterra and its links with Eltham. “It’s a mutually beneficial relationship,” she says. “The dairy industry is a vital part of Taranaki’s economy – dairy production and processing contributes around 10% of the region’s GDP and a similar level of employment, and Fonterra sits at the heart of that contribution.

“However, the benefits of Fonterra’s presence in Taranaki goes far beyond that, extending to regional pride, perceptions about Taranaki, and flow-on effects to many other industries.

“In return, the confidence Fonterra shows in the region, and in particular Eltham with its recent investments, is rewarded with a commitment and pride from the community, an available, experienced and stable workforce, and of course, the close proximity to its raw material source.”

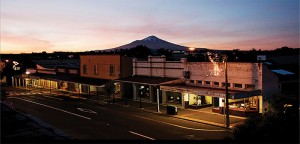

You can only imagine Eltham’s pioneering ghosts nodding their heads proudly at that sentiment. In a town of firsts, the gargantuan efforts of settlers is never as tangible or obvious as in this little settlement – nestled under the mountain 50km from the nearest city that just on 2000 people – and our largest cooperative – call home.

Kathryn Calvert – editor of NZ FOODtechnology.