Revenue for this market has grown significantly in the past five years and it has been less affected than other agricultural industries by the adverse weather and global events during this time. The industry has also benefited from innovative equipment and efficient production methods which are allowing growers to produce consistently high-quality produce, and meet the stringent demands of the retail market.

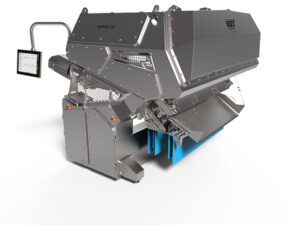

Rising capital investment by the larger players is helping to increase yields, improve quality and lower unit costs so they can capture the retail market. Digital sorting technology is also a savvy investment for expanding operations and earlier this year, Key Technology introduced the VERYX® Digital Sorter for fresh cut, hydroponically grown leafy greens.

“Hydroponic growers want every single leaf to be perfect, “ said Marco Azzaretti, Director of Marketing at Key.

“Veryx is the only belt-fed leafy greens sorter which can inspect product entirely in-air with top and bottom sensors to see all sides of the product with no blind spots, enabling VERYX to eliminate more FM and defects.

“Hydroponic greens are a premium product which typically cost two or three times the price of traditional, field-raised greens.

“VERYX can remove imperfect, misshapen, discolored, bruised, broken or torn greens and is significantly faster than manual inspection.

Consistent identification of foreign objects allows an operation to produce the same high-quality product, day after day. Each system can be customised to meet the exact needs of the producer, including the nuances of specific varieties and regional differences.

Next-generation sensor technology and intelligent software is able to collect, analyse and share data to reveal patterns, trends and associations.

“In addition to processing leafy greens, digital sorters from Key Technology are extremely versatile and suitable for a range of other produce — including fruits, vegetables and nuts.

For more information, please contact Heat and Control at [email protected], or visit www.heatandcontrol.com.