This means the juice or milk-based mixed drink is treated in its own dedicated process, while the fruit chunks, measuring up to 10mm x 10mm x 10mm, are pasteurised elsewhere in a separate shell-and-tube heat exchanger with interior cross-corrugated tubes.

To ensure gentle product treatment geared to maximised quality, Krones has developed the entire process technology required.

Rigorous separation and gentle product treatment are also continued in the filling process, featuring the company's new FlexiFruit pre-dosing equipment for fruit chunks or pulp.

In the pre-dosing system, first the fruit chunks are inserted into the bottles, and then the juice or the milk-based mixed drink is added in the main filler. This twin-flow process is already being used with great success.

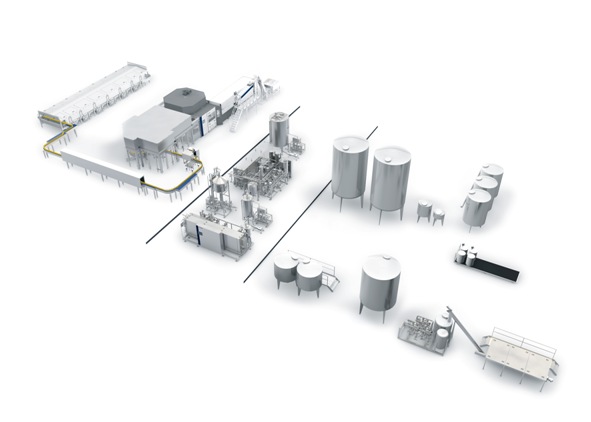

Thanks to holistic systems engineering, Krones is able to offer a seamlessly integrated concept subsuming both process and filling technology.

Some time ago Krones launched its own EvoGuard series of valves, which includes all the valve types required in a beverage plant. Starting with disk valves in modularised design, plus single-seat valves for simple shutoff operations at pipes, double-seal valves as an affordable alternative for media separation, all the way through to double-seat valves for highly automated function sequences.

The very latest innovation, to be premiered at the Anuga FoodTec trade fair in Cologne from March 27-30, is aseptic valves that are used as seat valves for hermetically dependable shutoff of pipes or as aseptic double-seat valves for separating media in aseptic and sterile processes.

For more information:

Krones Pacific

Tel: 09 572 8048

Email: [email protected]