EMULSIFICATION TECH FOR FUNCTIONAL FOOD PRODUCTS

EMULSIFICATION TECH FOR FUNCTIONAL FOOD PRODUCTS

As the demand for formulating food emulsions with enhanced nutritional value (such as low calorie, encapsulated bio-actives and targeted release) becomes increasingly sophisticated, new technologies are needed to replace current blending methods at a manufacturing scale, most of which are still based on principles of homogenisation.

Fundamentally aggressive and difficult to control, this method requires a high energy input which can damage ingredients and result in formulations with a broad particle size distribution that affects the quality and performance of the end product. Although the recent development of microfluidic devices can provide precisely controlled monodispersity, the technique still cannot deliver industrially meaningful volumes.

To remove this roadblock, Micropore’s patented range of advanced crossflow (AXF) equipment offers what ATA Scientific describes as a “next generation, fully scalable technology enabling continuous production of emulsions, double emulsions, encapsulated and bio-engineered particles in a very energy and resource efficient small footprint”.

Able to protect delicate ingredients, this fully scalable, continuous method delivers a narrow and controllable particle size distribution from development at micro litre scale through to kilotonne manufacturing if required.

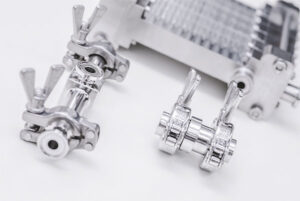

Micropore equipment is constructed of entirely food grade stainless steel with industry standard hygienic fittings. While other membrane emulsification methods use glass or ceramics which are prone to blockages, says ATA Scientific, Micropore uses laser micro-drilled electropolished stainless-steel membranes.

It overcomes difficult challenges in formulations with particular successes in the production of low-fat dairy foods, improving the texture and stability of meat-free products and dispersing high viscosity ingredients such as manuka honey evenly in chocolate.

For more information or to book a demonstration contact ATA Scientific on +61 2 9541 3500 or visit www.atascientific.com.au.